When it comes to protecting your products during transit or storage, foam packaging inserts are an invaluable resource. Their versatility, durability, and customization potential make them one of the best options for a variety of industries. Whether you are shipping delicate electronics, fragile glassware, or even medical equipment, foam packaging inserts offer a tailored solution to ensure that your products reach their destination in perfect condition.

In this article, we’ll explore the benefits of custom foam packaging, why it’s an essential part of modern shipping and storage solutions, and how you can make the most out of foam packaging inserts to optimize your business’s logistics. By the end of this guide, you’ll have a thorough understanding of how to effectively implement foam packaging for your needs.

What is Custom Foam Packaging?

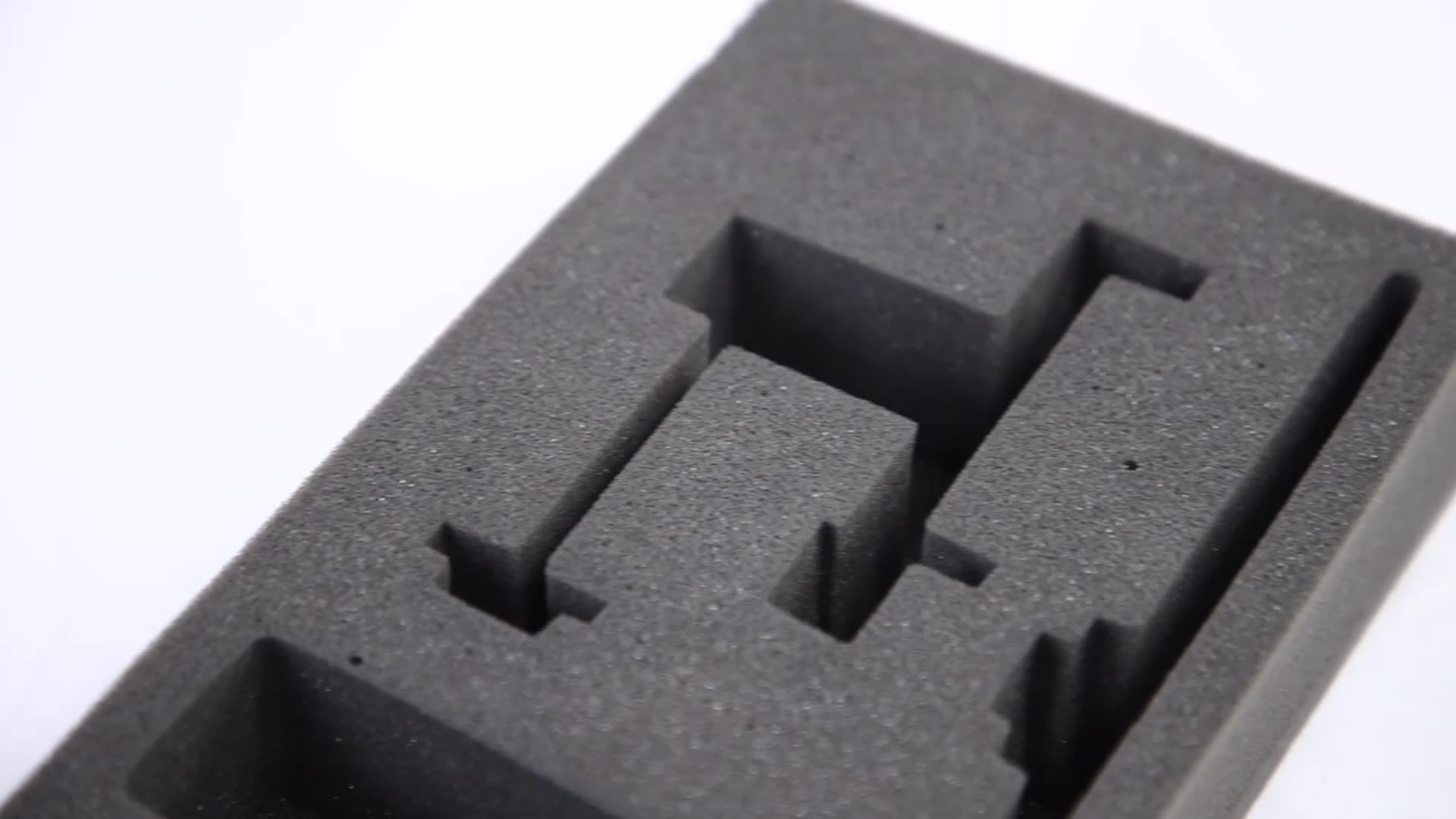

Custom foam packaging refers to foam materials that are designed specifically to fit the dimensions and shape of the products being packaged. These foam inserts are molded or cut to securely hold each item in place, preventing damage during transportation. They provide cushioning, shock absorption, and added protection against impacts, vibrations, and other potential hazards during handling.

Types of Foam Packaging Inserts

There are various types of foam packaging inserts available, each catering to different needs and types of products. The most common options include:

- Polyurethane Foam Inserts: Known for their excellent cushioning properties, these are perfect for products that require soft and flexible protection. They are commonly used for delicate electronics, medical instruments, or high-end cosmetics.

- Polyethylene Foam Inserts: With higher resistance to compression, polyethylene foam inserts are better suited for heavy-duty applications. They are often used for shipping large or bulky items, such as machinery, automotive parts, or large glassware.

- Ethafoam Inserts: A specialized type of foam that combines both flexibility and durability, often used for fragile items that require extra protection. It also has excellent moisture resistance properties.

- Memory Foam Inserts: A more luxurious foam option, memory foam conforms to the shape of the product it holds, providing custom-tailored protection. These inserts are typically used in high-end packaging for fragile items like watches, jewelry, or luxury electronics.

Why Choose Foam Packaging Inserts?

1. Superior Protection for Fragile Items

The most significant advantage of using foam packaging inserts is their ability to offer excellent protection for fragile or sensitive items. Foam is lightweight, yet durable, and can absorb shocks and vibrations that could otherwise cause products to break or get damaged. This feature is crucial for industries like electronics, medical devices, and fragile glassware, where even minor damage can lead to major losses.

By customizing foam packaging inserts, you can ensure that your products fit perfectly into the packaging, preventing unnecessary movement that could lead to breakage. The foam will absorb the impact instead, ensuring the product reaches its destination safely.

2. Customizable Design

One of the key benefits of custom foam packaging is its high level of customization. Foam packaging can be tailored to the exact shape and size of your product, ensuring a snug and secure fit. This is especially important for irregularly shaped items that may not fit in traditional packaging materials, like cardboard.

With custom foam packaging inserts, you can create foam molds that perfectly match your products’ contours, providing optimal support and protection. Customization allows you to choose from a variety of foam types, densities, and colors, offering flexibility in design and functionality.

3. Cost-Effective Shipping Solutions

While custom foam packaging may initially seem like a higher investment, it can actually save money in the long run. High-quality foam inserts reduce the likelihood of damage during shipping, which means fewer returns, replacements, or refunds. By minimizing damage, you also avoid the additional costs associated with customer dissatisfaction, product repairs, or lost goods.

Additionally, using custom foam packaging inserts can reduce the overall weight of your shipment, which may lower shipping costs, particularly when compared to heavier protective materials like wood or plastic. Lightweight foam packaging allows businesses to save on transportation expenses while maintaining protection for fragile items.

4. Sustainable Packaging Option

As consumers and businesses alike become more conscious of environmental impact, many packaging suppliers now offer sustainable foam packaging solutions. Materials like biodegradable and recyclable foams provide the same level of protection as traditional packaging while being more eco-friendly.

Opting for foam packaging inserts made from sustainable materials can enhance your brand’s reputation, especially if your target market values environmentally responsible business practices. It’s a win-win situation—protect your products while helping reduce your carbon footprint.

5. Enhanced Brand Image

Custom foam packaging inserts can also help elevate your brand image. By choosing high-quality foam packaging, you not only provide superior protection for your products, but you also show your customers that you care about delivering top-notch service. Custom foam inserts can be designed with your branding in mind, incorporating your logo, colors, or other branding elements into the foam material. This added touch reinforces your brand identity and improves the unboxing experience for your customers.

6. Versatility Across Industries

Foam packaging is widely used across many industries due to its versatility. Whether you’re in the electronics, medical, automotive, or retail sectors, foam packaging inserts can be adapted to protect a wide range of products. From delicate electronics like smartphones and laptops to fragile collectibles and even industrial components, foam packaging inserts provide an effective, reliable solution for various product types.

read the latest blogs here

How to Implement Custom Foam Packaging in Your Business?

1. Identify Your Needs

Before you begin sourcing custom foam packaging, it’s essential to evaluate the specific needs of your products. Consider the following:

- Size and Shape: Are your products uniform in size or irregularly shaped?

- Fragility: Do your products require soft, cushioning protection, or do they need more rigid support?

- Weight: Are your products light or heavy? Choose the appropriate foam material based on weight requirements.

Understanding your product’s unique characteristics will guide you in selecting the right type of foam insert.

2. Partner with a Reliable Foam Packaging Supplier

Choosing a reputable supplier is crucial to ensure you get high-quality foam inserts that meet your specifications. Look for suppliers that specialize in custom foam packaging and have experience working with businesses in your industry. A good supplier will work with you to design foam inserts that perfectly match your product’s dimensions and provide the necessary protection.

3. Design the Foam Insert

Once you’ve chosen a supplier, you’ll need to collaborate on designing the foam inserts. This may involve providing product samples or detailed specifications. The supplier will then create a prototype or sample for you to test. Make sure to thoroughly test the insert to ensure it offers adequate protection before committing to a bulk order.

4. Test and Evaluate

It’s crucial to evaluate the foam packaging inserts in real-world conditions. Consider running tests where you simulate the packaging process, including shipping and handling, to ensure that the inserts offer the desired level of protection. If any issues arise, discuss them with your supplier to make the necessary adjustments.

Conclusion

Incorporating custom foam packaging inserts into your packaging strategy is a smart choice for businesses that want to protect their products, reduce damage, and enhance their brand image. Whether you’re dealing with delicate electronics, glassware, or industrial equipment, foam inserts offer a customizable, reliable, and cost-effective solution to ensure the safety and integrity of your items during transit.

By following the steps outlined in this article, you can implement custom foam packaging in your business with ease. Not only will this improve your shipping and handling processes, but it will also contribute to customer satisfaction and long-term success.