The proper installation of industrial machinery is crucial for ensuring optimal performance, safety, and longevity. Whether setting up new equipment or relocating existing machinery, precise installation procedures are essential to prevent operational failures, reduce downtime, and maintain workplace safety.

This guide covers the key aspects of industrial machinery installation, including planning, safety regulations, tools required, and best practices to achieve seamless operations.

What Is Industrial Machinery Installation?

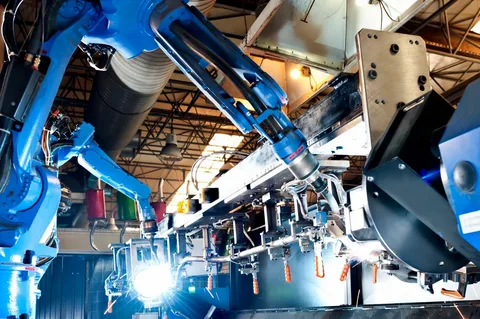

Industrial Machinery Installation refers to the process of assembling, positioning, and configuring heavy equipment and machinery used in manufacturing, construction, and other industries. The process includes:

- Transporting and positioning machinery

- Securing the foundation and structural alignment

- Connecting electrical, hydraulic, and pneumatic systems

- Testing and calibrating equipment

- Ensuring compliance with safety and operational standards

Proper installation enhances efficiency, productivity, and safety, reducing costly downtime and maintenance issues in the long run.

Steps in Industrial Machinery Installation

Installing industrial equipment requires a systematic approach to ensure precision and safety. Below are the key steps involved:

Pre-Installation Planning

Before the actual installation, thorough planning is necessary to avoid delays and complications. This includes:

- Reviewing manufacturer installation manuals and specifications

- Conducting site assessments for space, load-bearing capacity, and environmental conditions

- Identifying necessary power, fluid, and ventilation requirements

- Coordinating with engineers, technicians, and safety officers

Site Preparation

A properly prepared site ensures a safe and efficient installation process. This involves:

- Clearing and leveling the installation area

- Checking for proper flooring, anchoring points, and structural reinforcements

- Ensuring adequate lighting and ventilation

- Installing required utility connections (electrical, hydraulic, pneumatic)

Machinery Transport and Positioning

Moving heavy equipment requires specialized techniques and tools, such as cranes, forklifts, and skates. Key considerations include:

- Using load-bearing supports to prevent structural damage

- Aligning the machinery according to floor plans and operational needs

- Implementing shock-absorbing techniques to prevent damage during transport

Mechanical Assembly and Anchoring

Once in position, machinery must be properly assembled and secured to ensure stability and minimize vibrations. This step involves:

- Installing bolts, frames, and brackets

- Ensuring proper alignment with laser leveling or dial indicators

- Verifying that all moving parts are free from obstructions

Electrical and Utility Connections

Industrial machinery requires proper electrical, hydraulic, and pneumatic connections for seamless operation. This step includes:

- Connecting power supply lines and testing voltage compatibility

- Installing control panels, sensors, and automation systems

- Checking for potential leaks or pressure issues in fluid connections

Calibration and Testing

Before full-scale operations begin, machinery must be tested and calibrated to ensure optimal performance and compliance. This includes:

- Running initial dry tests to check movement and alignment

- Configuring software and automation settings

- Conducting load testing to verify stability and efficiency

- Ensuring compliance with industry regulations and safety standards

Final Inspection and Documentation

A final inspection checklist ensures all systems function correctly before the equipment is operational. Documentation should include:

- Installation reports detailing alignment, torque settings, and initial test results

- Maintenance schedules to keep machinery running efficiently

- Compliance certifications ensuring adherence to OSHA and ISO standards

Safety Considerations in Industrial Machinery Installation

Safety is a top priority when handling heavy machinery installation. Below are key safety measures to follow:

Conduct Risk Assessments

Before starting, a risk assessment must be conducted to identify hazards related to lifting, electrical connections, and machine operation.

Use Personal Protective Equipment (PPE)

Technicians should wear:

- Hard hats for head protection

- Safety goggles for eye protection

- Gloves for handling sharp components

- Steel-toe boots to prevent foot injuries

Follow Lockout/Tagout (LOTO) Procedures

LOTO procedures prevent accidental machine startups, ensuring worker safety during installation and maintenance.

Proper Lifting Techniques and Equipment

Lifting and positioning heavy machinery should be done using hydraulic lifts, cranes, and forklifts to avoid accidents and injuries.

Adhere to Electrical Safety Standards

Industrial equipment must comply with National Electrical Code (NEC) and OSHA safety guidelines to prevent short circuits and power surges.

Implement Emergency Response Plans

Having a first-aid kit, fire extinguishers, and trained emergency responders on site minimizes risks in case of accidents.

Challenges in Industrial Machinery Installation and How to Overcome Them

Despite careful planning, machinery installation can present challenges. Here’s how to address them:

Limited Space and Accessibility

- Use modular installation techniques for tight spaces

- Consider customized lifting and positioning solutions

Unexpected Structural Weaknesses

- Conduct structural integrity assessments before installation

- Reinforce floors and walls if necessary

Equipment Misalignment

- Use laser alignment tools for precision

- Implement vibration analysis to detect misalignments

Compliance and Regulatory Issues

- Work with certified industrial installation experts

- Maintain updated documentation for audits and inspections

Why Hiring Professional Industrial Machinery Installers Matters

Hiring expert machinery installers ensures efficiency, compliance, and minimal downtime. Professional installation companies offer:

- Trained and certified technicians for accurate setup

- Specialized lifting and positioning equipment

- Compliance with OSHA, ISO, and NEC standards

- Post-installation support and maintenance services

Conclusion

Proper industrial machinery installation is critical for safety, efficiency, and long-term performance. By following best practices, safety protocols, and expert recommendations, businesses can ensure seamless equipment setup and prevent costly breakdowns. Investing in professional installation services and advanced alignment tools can further optimize operational efficiency and workplace safety.